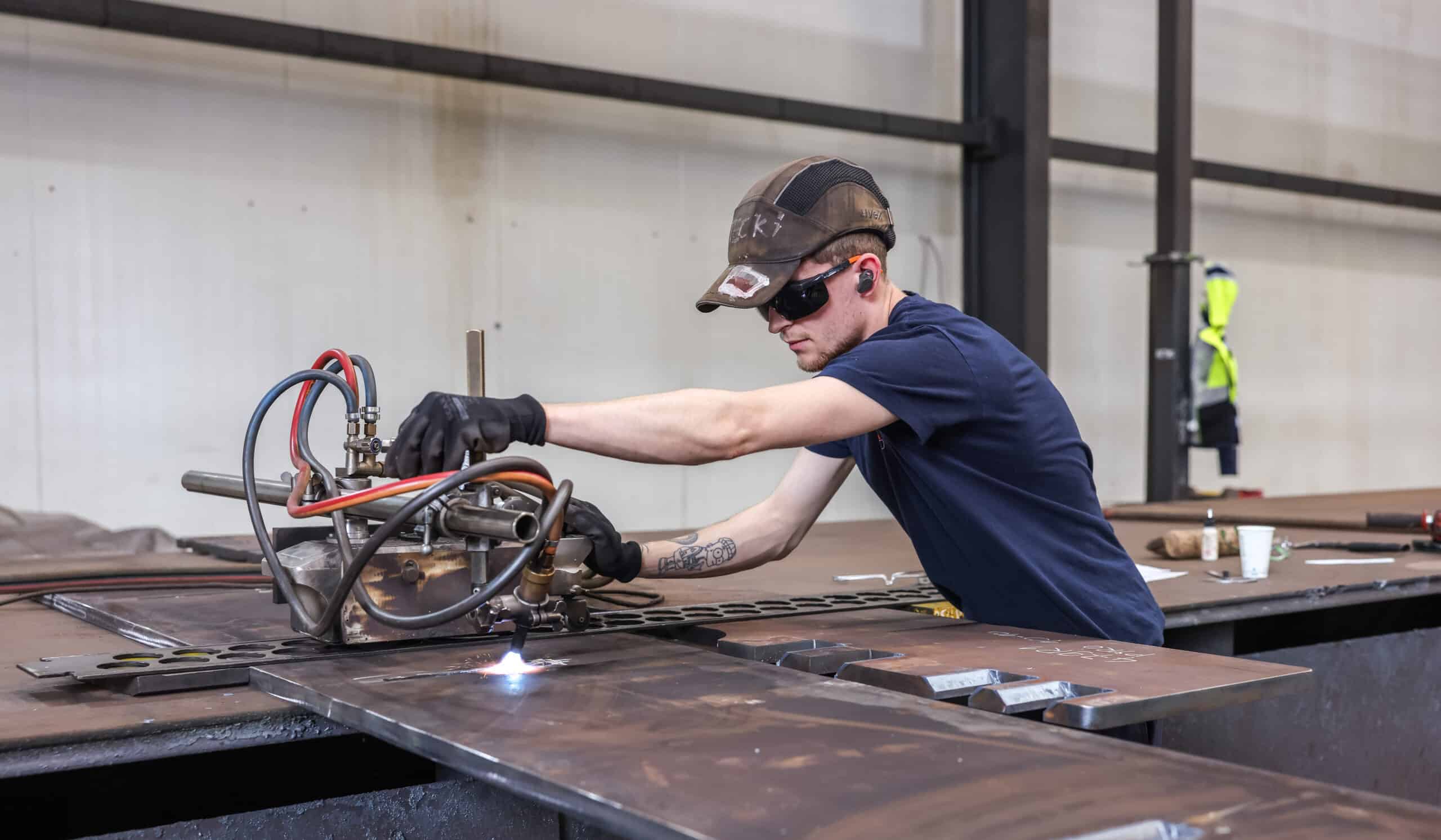

Cutting steel

Cutting for precisely cut and processed steel

Europe Steel Center takes care of your steel into directly usable finished product for your project. We cut your steel to exactly the right size with advanced cutting methods and process it at a high level with our modern profiling techniques.

We cut your steel to exactly the right size using oxyfuel, plasma and laser processes with advanced cutting methods.

State-of-the-art cutting machines

With our modern cutting machines, we produce even the most complex customised work in detail. From oxyfuel cutting in thick steel, to high-precision laser cutting. We continue to improve and innovate our cutting performance, to keep offering you the best in steel.

- Fiber Laser

- Oxy-fuel

- Plasma

- Laser

- Robot cutting

Operations

- Chamfering

- Complex bevelling

- Blasting

- Flattening

Services

- Inspections

- Additional testing

- Marking

- Packaging

Our services in steel cutting and processing

Europe Steel Center has everything in-house to deliver your steel products completely according to the most precise specifications and the strictest standards and requirements. Discover our services in cutting.

Cutting

We are at the forefront of innovative cutting methods. With our modern cutting machines, we produce even the most complex customised work from large dimensions of steel, precisely to the last detail. From oxyfuel cutting in thick steel, to high-precision laser cutting.

Chamfering

With our advanced cutting machines, we make the most complex weld edge preparations with incredible speed and precision. So your steel product is ready for immediate use.

Shotblasting

With our shotblasting machine, we shotblast your steel after cutting, so you can use it directly into your production process.

Flattening

With our flattening machine, we ensure flat material and can deliver the material to the applicable standard.

Complex Bevelling

Europe Steel Center is specialised in complex bevelling, we apply a transition from thick to thin in your profiled steel plates with a high quality standard. A craftmanship that we are proud of.

Edge Preparation

All our cuts are deburred as standard. We can also provide cutting edges with R2 rounding on request.

Inspect

We check your steel for quality, dimensions and conformity with specifications and standards. We also supervise inspections by third-party authorities or customer inspections.

Marking

With our comprehensive marking methods, we ensure optimal traceability. Have markings such as (setting) lines and part numbers made, or have other information such as heat numbers and PO numbers stamped.

Packaging

Ask us about the possibilities of having your steel specially packed, for air freight for example.